Henry Hurt: Master Knitter

How The Artisan Craft Lives On

Henry was one of the last, if not THE last, handframe knitting apprentice. He entered into a 7-year apprenticeship scheme, under the firm’s factory foreman, Mr Jeff Oxley.

Reminiscing on his working life, Henry comments it was a hard slog learning the job. As his first task, Henry remembers his father, Leslie, (founder George’s lad) asking him to dismantle a handframe into its parts and then re-assemble it! Jeff Oxley helped with a watching eye over “the lad’s lad” and the handfame was ‘recruited’; a knitter’s phrase meaning refurbished or re-conditioned. Henry went on to work in this Handframe for several years, being paid for what he knitted.

Henry recalls he also helped his father elsewhere in the firm. “My Dad did all the packing and invoicing. So, in those early years, I helped him with this too”. The Jaeger Company was one of the firm’s best clients at this time. So, a lot of the hand knitted pieces from Henry’s handframe went to Jaeger. Exquisitely hand knitted pieces, beautifully hand finished, has always been the firm’s focus.

Leslie Hurt, was also competent in a handframe. Henry explains that his father Leslie worked in the frames through WWII. It was the only time in the firm’s history a night shift was introduced. As some of the staff were in the ‘Home Guard’, they performed duties elsewhere during the day. So, true to the tradition, the artisan craft of handframe knitting was handed down from Father to Son.

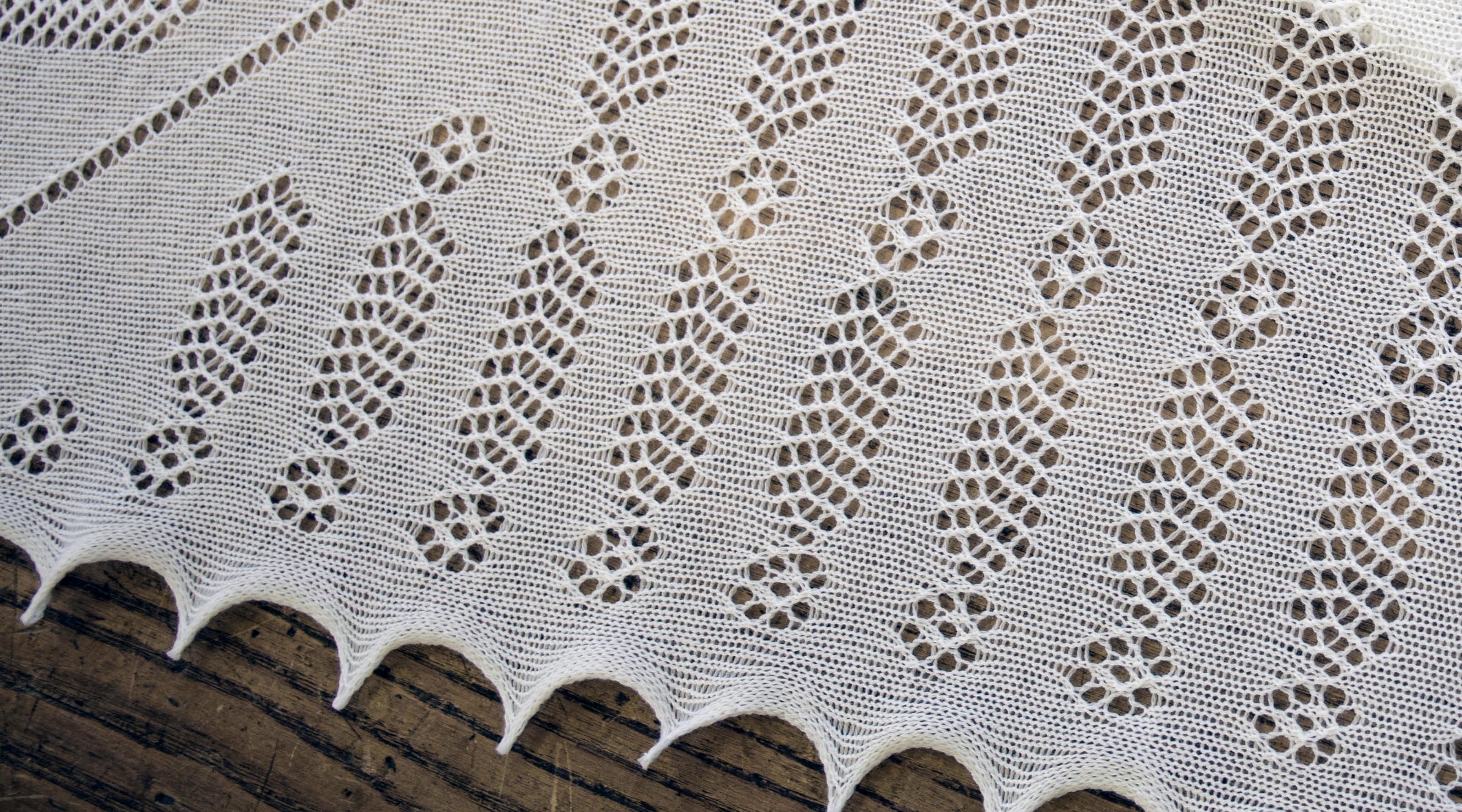

In 1966, Henry succeeded in adapting a powered knitting machine to knit the lacy shawls synonymous with handframe knitting. This was a milestone for the young Henry, now running the firm as boss and factory owner. Henry could see the days of knitters sitting in handframes were numbered and started to knit more regularly on the modern machinery. It had taken Henry years of research to arrive at this point, reading trade magazines, attending trade fairs, speaking to other knitwear firms. This research enabled Henry to continue the firms unique style of knitting, beyond the last few handframe knitters.

The first powered machine was set up in the factory office, between Henry’s desk and the Secretaries’. They both worked around it. Without realizing, the secretary swiftly learned how to operate the machine for when the boss wasn’t present, listening out for certain noises and adjusting it here and there!

By the early 1970’s, Henry had acquired several second hand machines. At the point he had three of these powered machines, he could see the future of the firm was secured. By this stage, just four of the old boys - the handframe knitters – were still active. The next machine Henry bought was a new one. Henry worked this machine hard and made it earn its keep! Luckily, orders were healthy during this period of transition, so Henry kept the powered machines working long days and weekends.

One of the ‘old boys’, Harold Oxley, died in 1977. He was a dedicated character who was able to knit up to 60 scarves in a day – as many as any modern knitting machine today! With the help of his wife winding his yarn, coming to work on the back of their tandem bike.

Jeff Oxley, the last of the ‘old boys’, retired in the early 1980’s but the firm couldn’t keep him away. Jeff continued to knit in his handframe until 1986, when ill health prevented him from coming in to the Shawl Factory. By the time Jeff passed away, Henry Hurt had completed the transformation. A ‘knit shop’ building, to accommodate a dozen or more modern commercial knitting machines, had been built alongside the original Shawl Factory.

In my opinion, Henry explains, choosing the slower, but more sophisticated commercial knitting machines proved to be the most important innovation in the firm’s development. In contrast, more expensive machines, with the capability to knit more quickly, could not do the same work. It's a question of quality over quantity. A value G.H.Hurt & Son still pursues today.

In his last few years, Henry continued to work in the handframes, still housed in the original Shawl Factory building, showing guests and visitors the original Artisan Craft. He also took the time to train several Knitwear Students over the years. Importantly, G.H.Hurt & Son continue to make knitted lace pieces, in the same style of the framework knitter before. So, the craft lives on…